Protein Padding Machine

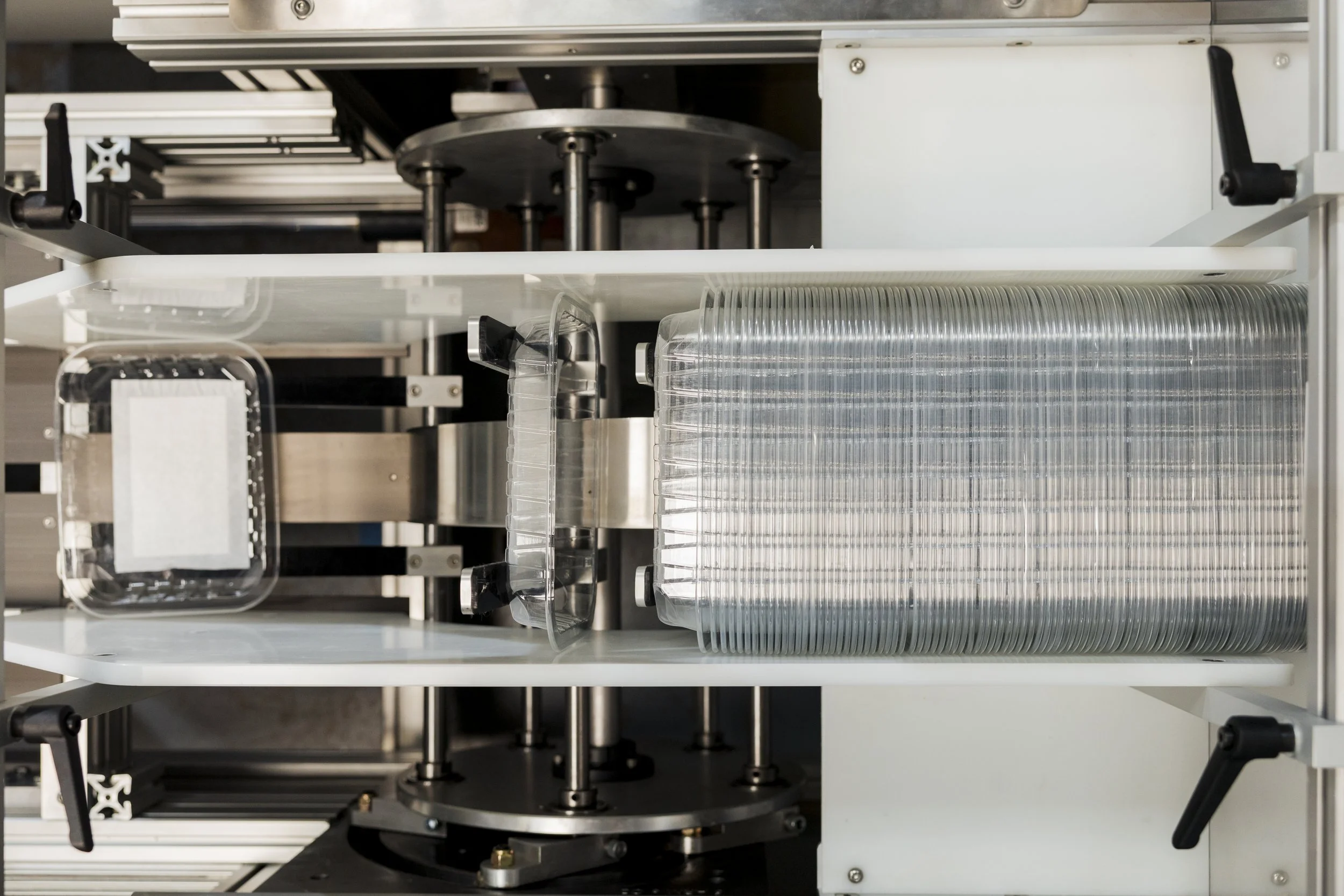

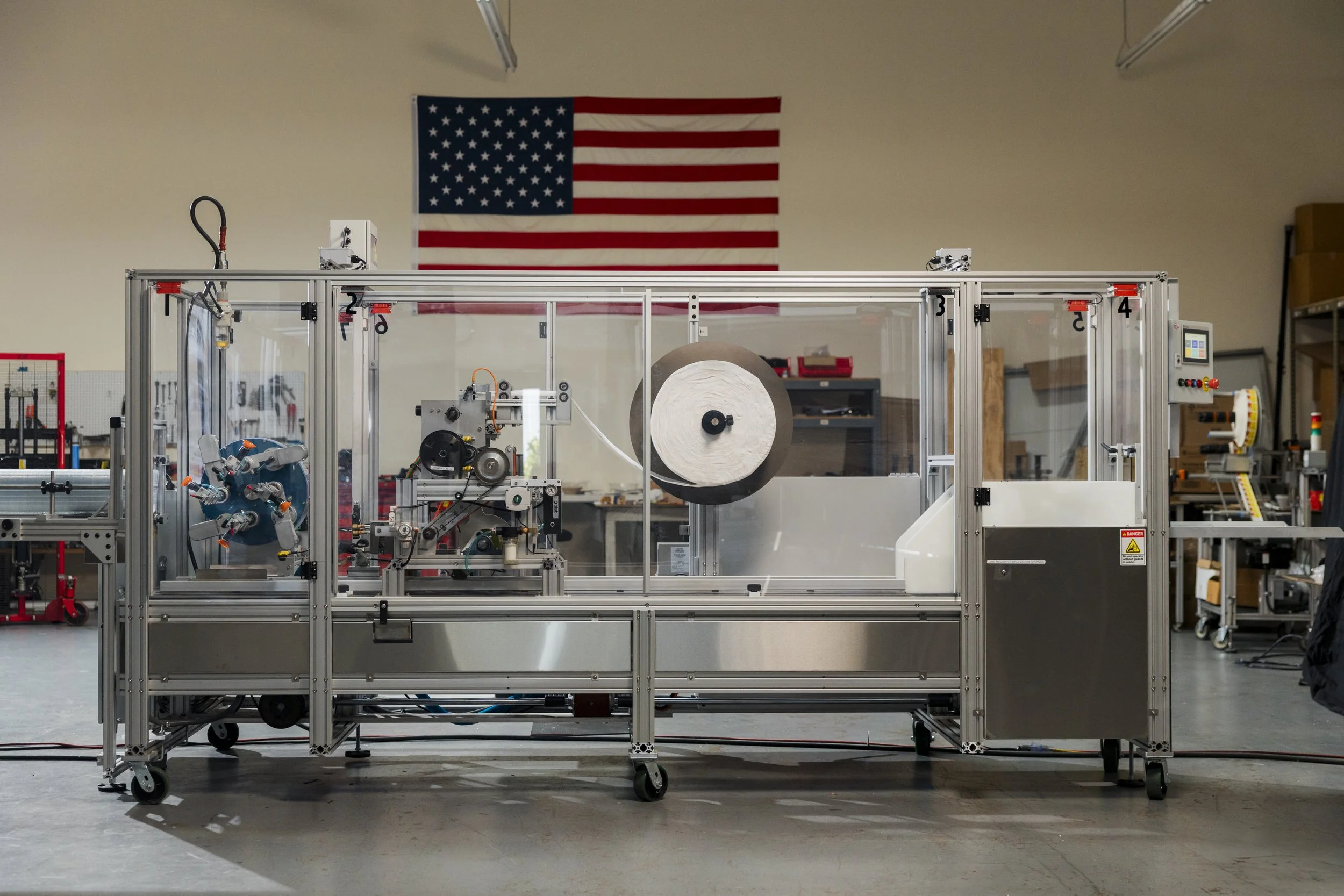

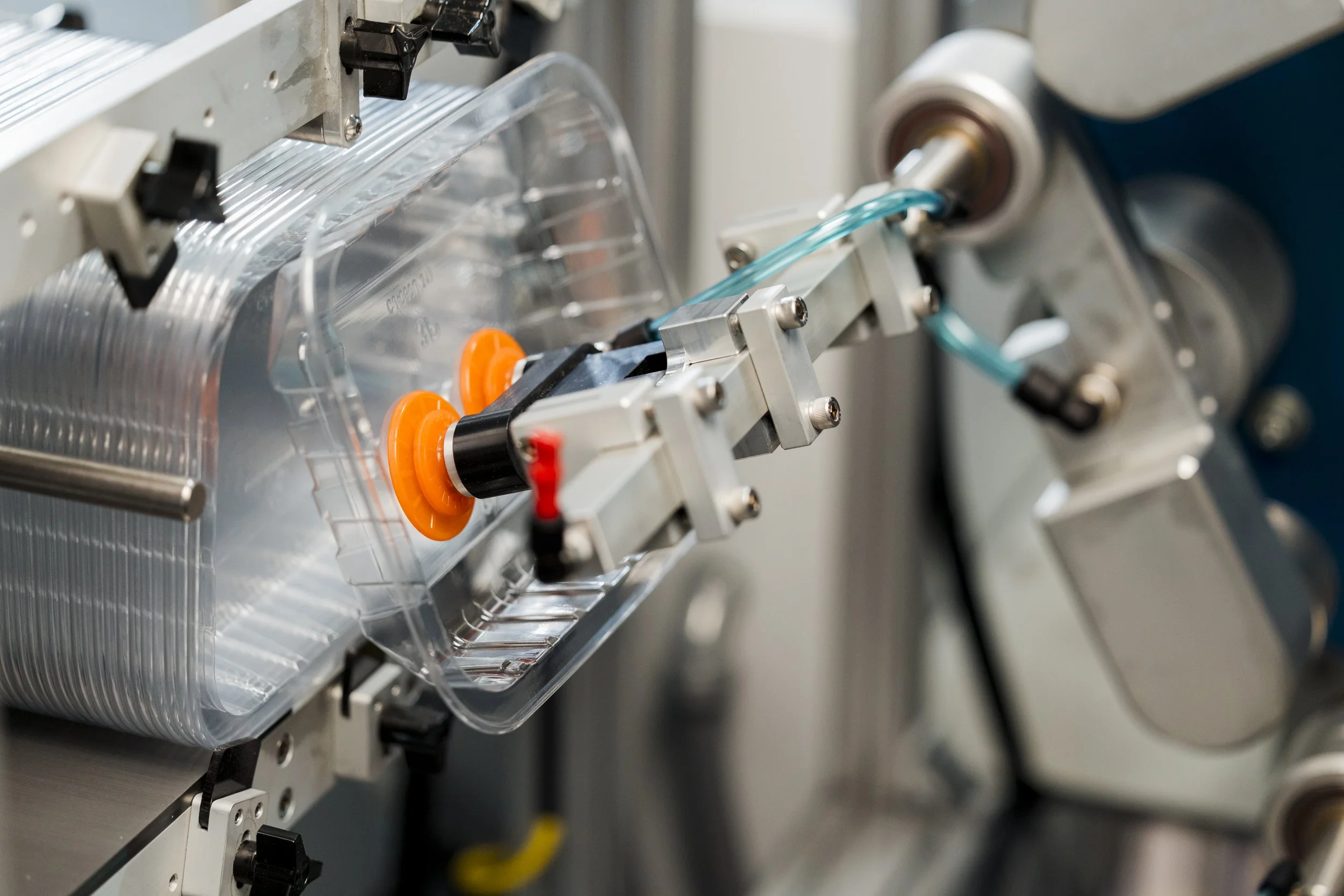

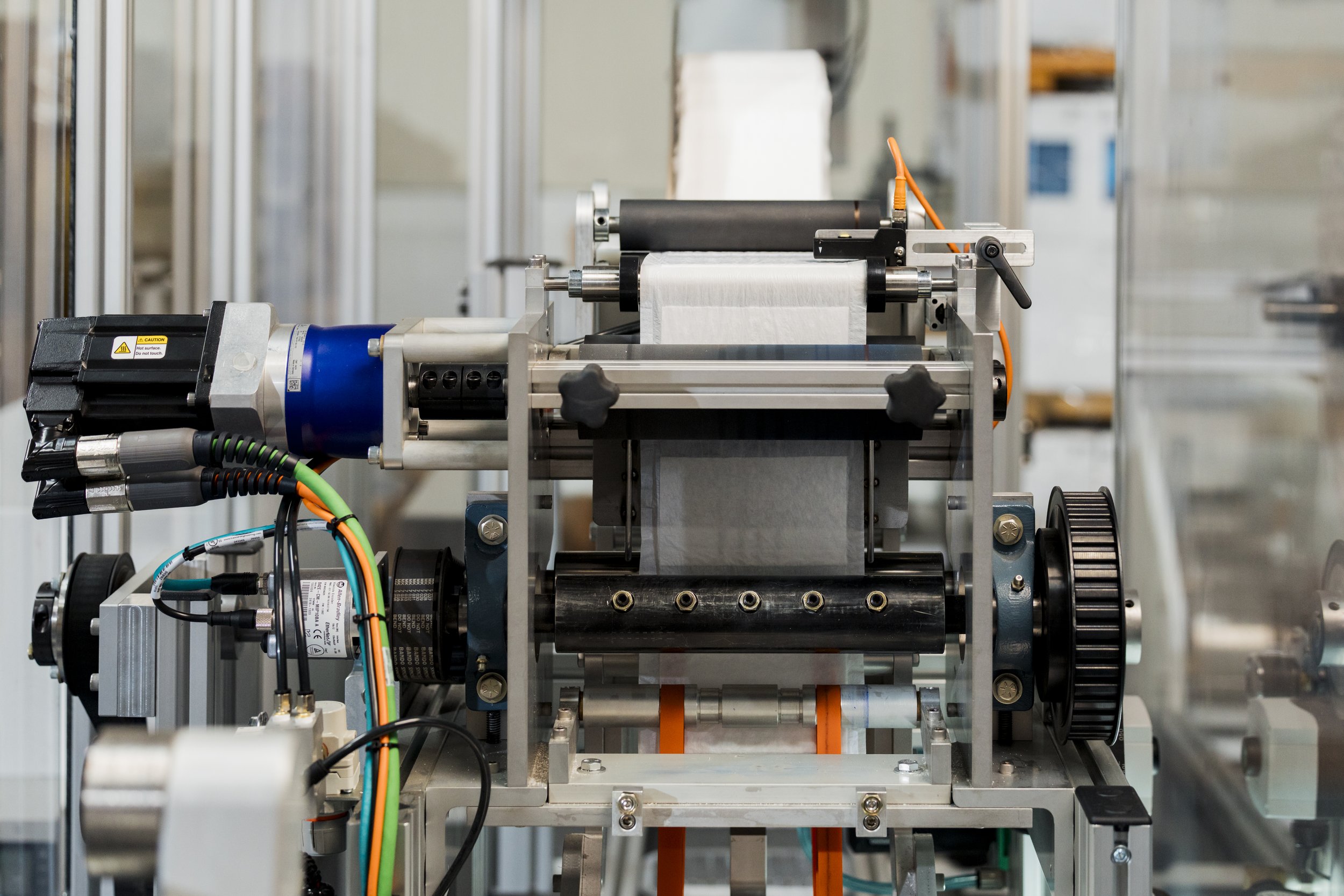

We have built a specialized Padding Machine that works for meats, poultry, seafood and alternative proteins. This fully integrated system denests thermoformed trays, applies glue, inserts absorbent material, and restacks trays at speeds up to 170 containers per minute. The result is faster throughput, cleaner operation, and consistent product quality that keeps pace with demanding packaging lines.

Key Benefits:

• High Throughput: Processes up to 170 containers per minute for trays, maintaining speed and precision across multiple container sizes.

• Seamless Integration: Linear design maintains smooth material flow from denesting through pad application and restacking.

• No-Tool Changeovers: Modular construction allows easy size changes between common 6–12 oz. common clamshells or trays.

• Minimal Maintenance: Dry-running design eliminates over-greasing and reduces contamination risks.

• Operator Friendly: Full-length visibility and central HMI control enable easy monitoring and quick setup.

• Proven Reliability: Built for continuous 24/7 operation with components and design refined over 15+ years of field performance.